Quality – high-quality materials, energy efficient implementation

ROOF TIMBER TRUSSES

For roofs, ceilings and other structures

For private houses, multi-story houses, farm buildings

Footbridges, concrete forms, industrial buildings

FACADE STRUCTURES OF ROOFS – VARIOUS ROOF SOLUTIONS

As an independent part of the technical solution, our company offers roof facade structures. Like any construction project, roof trusses differ in terms of their application and implication. Calculations of projected roof structures take into account site distinctions, specific wind and snow load.

There are several types of trusses classified as follows: flat trusses; shed roof or gable roof solutions. Such pressed roof trusses can also be used for camp ceiling which include wall covering, wall and roof components, thus saving a lot of time.

Taking into account numerous aspects of a roof type, our company cannot quickly set its average price, since it requires additional time.

However, at your disposal is our wooden ROOF COVER CALCULATOR, where according to the data provided by you, you can find out the approximate price.

ROOFING TECHNOLOGIES IN SOLUTIONS

Bus bars produce a substantial economic effect. Complex roof structures require 30% of timber less than conventional roofing.

The MiTek computer program helps to draw up and calculate required parameters.

On the other hand, a Randek 35t press with MiTek perforated nail plates 1.5-2.0 mm thick provides for actually infinite solutions.

This product envisages construction of up to 12 m of a mezzanine / attic floor without extra supports, with an option to lay various service lines using available construction space.

It is perfect to replace the old roof or to build a new one, for rapid accomplishment and good outcomes.

To manufacture roof trusses we use only certified Latvian timber of C24 wood strength class, and Silver Standart Houses is one of the few Latvian manufacturers entitled to mark the product with the CE mark, thus conforming to LVS EN 14250 standard.

OUR ADVANTAGES

We combine state-of-the-art technology, commercially optimised processes, efficient logistics, and a short assembly timeline to deliver outstanding results. While the foundation is being laid on-site, our factory manufactures fully finished wall and roof panels under controlled microclimate conditions.

For a typical 150 m² house, production of the required panels takes no more than two weeks, with on-site assembly completed in just 2 to 5 days. This streamlined process offers significant time savings—up to 40% faster than traditional construction methods.

All panels are delivered with windows and doors pre-installed, and in some cases, a composite façade is also included—ready for rapid, high-quality assembly.

According to a 2003 study by Bill Quigley, which compared three timber frame houses with three conventional modular homes, timber construction demonstrated significantly better energy efficiency in maintaining indoor temperatures.

The research found that timber panel houses consumed less energy to sustain higher average temperatures. In fact, increasing the temperature by 1°C in a timber frame home required 44% less energy than in a comparable modular house. As a result, heating costs in timber frame homes were shown to be 32% lower.

This highlights the importance of proper insulation in timber construction. A well-insulated timber building significantly reduces thermal losses, directly lowering energy consumption and overall running costs — making it a smart, sustainable choice for homeowners.

Timber panel buildings offer significant savings compared to traditional construction methods:

Up to 30% reduction in foundation costs – thanks to the lighter weight of the structure, smaller and less complex foundations are required.

Lower transportation expenses – prefabricated panels are compact and efficient to transport, reducing logistics costs.

Simplified and faster assembly – the lightweight nature of the components allows for a more straightforward and comfortable installation process on site.

These advantages make timber panel construction a cost-effective, time-saving solution without compromising on quality or durability.

Our manufacturing process uses only CE-certified raw materials, ensuring high-quality standards, safety, and full compliance with environmental regulations.

Timber is not only a renewable resource — it also supports a healthier way of living. Timber structures naturally promote both physiological and psychological well-being, helping to create spaces that feel calm, balanced, and in harmony with their surroundings.

By choosing timber, you’re choosing a material that fosters a strong, sustainable relationship between people and the environment.

One of the key advantages of our timber panel system is the ability to accurately determine the construction timeline, significantly reducing the risks of delays and uncertainty.

Compared to traditional building methods, on-site construction costs are substantially lower, as prefabricated wood panels require less time and labour.

Utility networks can be conveniently integrated within the wall structure, allowing for efficient planning and installation of service lines. Additionally, interior and exterior finishes can be completed simultaneously, as the materials used do not require drying time — unlike those in brick or masonry construction.

The result is a faster, more cost-effective, and highly coordinated building process from start to finish.

Through strict internal quality control and the use of carefully selected materials, our timber panel homes offer a high-quality living environment with a naturally balanced indoor microclimate. Key benefits include:

1. Natural Control of Air Quality and Humidity

Timber has a unique property known as equilibrium moisture, allowing it to regulate indoor air humidity naturally. It “breathes”, helping maintain a healthy and comfortable environment. This is further supported by mechanical ventilation systems with heat and moisture recovery, which monitor, automate, and optimise air quality throughout the home.

2. Excellent Thermal and Acoustic Insulation

Wood panel walls provide superior thermal performance and sound insulation compared to traditional brick. Their optimal weight and layered structure help create a peaceful, energy-efficient living space. Thoughtfully designed soundproofing ensures maximum comfort and quiet.

3. Reduced Dust Levels – Allergy-Friendly Living

Timber’s natural anti-static properties help prevent the build-up of static electricity, a key factor in household dust accumulation. As a result, timber homes typically contain lower levels of airborne dust, making them an excellent choice for individuals with allergies or respiratory sensitivities.

A properly constructed timber panel house is both durable and fire-resistant — offering far greater safety than many assume.

These homes are not simply “timber houses”, but carefully engineered structures made from specialised panels designed to limit oxygen access, which in turn suppresses fire spread.

Modern fire protection methods allow timber components to be treated with fire-retardant agents or fireproof coatings, significantly enhancing resistance. With the appropriate treatment, our wall panels can achieve a fire resistance rating of B-s1, d0, meeting strict European safety standards for limited flame spread, smoke production, and dripping.

At Silver Standard Houses, our roof trusses and wall panels are designed with low weight and compact structural efficiency, making them exceptionally well-suited for modern construction and logistics.

This lightweight design enables convenient handling, efficient transportation, and a significant reduction in delivery costs for prefabricated components. Combined with excellent energy efficiency, our structural elements ensure both high performance and practical benefits throughout the construction process.

At Silver Standard Houses, we stand by the quality of our work with comprehensive support and peace of mind for every client.

2-Year Aftercare Service

We provide a 2-year backup service for each completed construction project, during which any potential defects or damage will be promptly addressed and repaired.5-Year Structural Warranty

Our building frames are covered by a 5-year warranty, ensuring long-term durability and reliability of the core structure.

Your satisfaction and security are our priority — from project completion through to years of everyday use.

With our prefabricated system, you can build your home in any weather conditions. Simply prepare the foundation during the warmer months, and construction of the house can continue seamlessly, even through autumn and winter.

This flexibility allows for faster project timelines and minimal seasonal disruption, ensuring your new home stays on track — whatever the weather.

Prefabricated houses offer exceptional quality at a price point accessible to a wide range of customers. The final cost depends on the selected materials and the level of finishing or performance standards required — giving you flexibility to match your budget and needs.

These homes not only significantly reduce construction time, but also contribute to lower overall building costs, making them a smart, efficient choice for modern living.

roof construction solutions

We offer a range of durable and visually appealing roofing materials to suit your design preferences and performance requirements:

Bitumen shingles – lightweight, weather-resistant, and ideal for pitched roofs

Ranil sheets – robust and low-maintenance metal roofing with a clean, modern finish

Roof tiles – traditional aesthetic with excellent durability and thermal performance

Each option is compatible with our roof panel systems and selected based on the specific needs of your project.

For superior moisture control and weather protection, we use premium diffusion membranes from trusted brands such as Tyvek® and Rothoblaas.

Both systems offer:

High vapour permeability for effective breathability

Excellent water and wind resistance

Durability and UV stability

Reliable performance in timber frame and panel constructions

The choice between Tyvek® and Rothoblaas depends on the specific requirements of your project, including climate conditions, structural design, and energy performance goals.

Our building envelope solutions achieve U-values from 0.12 W/m²K, depending on the configuration and materials selected.

This high level of thermal insulation significantly reduces heat loss, contributing to excellent energy efficiency, lower heating costs, and a more comfortable indoor climate year-round.

We offer structural roof solutions using either traditional rafters or prefabricated roof trusses, selected based on your project’s design and load requirements.

Available dimensions:

145 mm

195 mm

220 mm

The appropriate size is determined by load-bearing calculations, taking into account snow load, roof span, roofing material, and overall building design.

For ceiling finishes, we use 12.5 mm plasterboard, offering a clean, durable surface that is ideal for painting or other decorative treatments.

Benefits include:

Smooth, uniform appearance

Good fire resistance

Effective sound insulation

Quick installation and easy maintenance

This standard ceiling finish complements both traditional and modern interiors, ensuring a high-quality result throughout the home.

We ensure a minimum insulation thickness of 300 mm, depending on the building’s intended use and energy performance requirements.

This level of insulation can be achieved either through the construction of a high-performance roof panel or by insulating the non-residential attic floor — both methods delivering excellent thermal efficiency and long-term energy savings.

A layer of 45 mm wooden laths is combined with 50 mm of additional insulation, enhancing both the thermal and structural performance of the building envelope. This setup improves energy efficiency and supports secure installation of interior finishes.

The roofing system includes a 30 mm layer of rigid stone wool insulation, combined with either:

45 mm timber lathing, or

18 mm OSB boards,

depending on the type of roofing material used.

This configuration ensures excellent thermal insulation, structural support, and compatibility with a range of roofing finishes.

As part of the roofing or wall assembly, we use Tyvek® Supro Plus, a high-performance diffusion membrane designed to provide superior weather protection while allowing moisture vapour to escape.

This membrane offers:

Outstanding water resistance

High vapour permeability

Exceptional durability and tear resistance

Integrated adhesive strips for airtight installation

Tyvek® Supro Plus contributes to a longer-lasting structure, improved energy efficiency, and a healthier indoor environment.

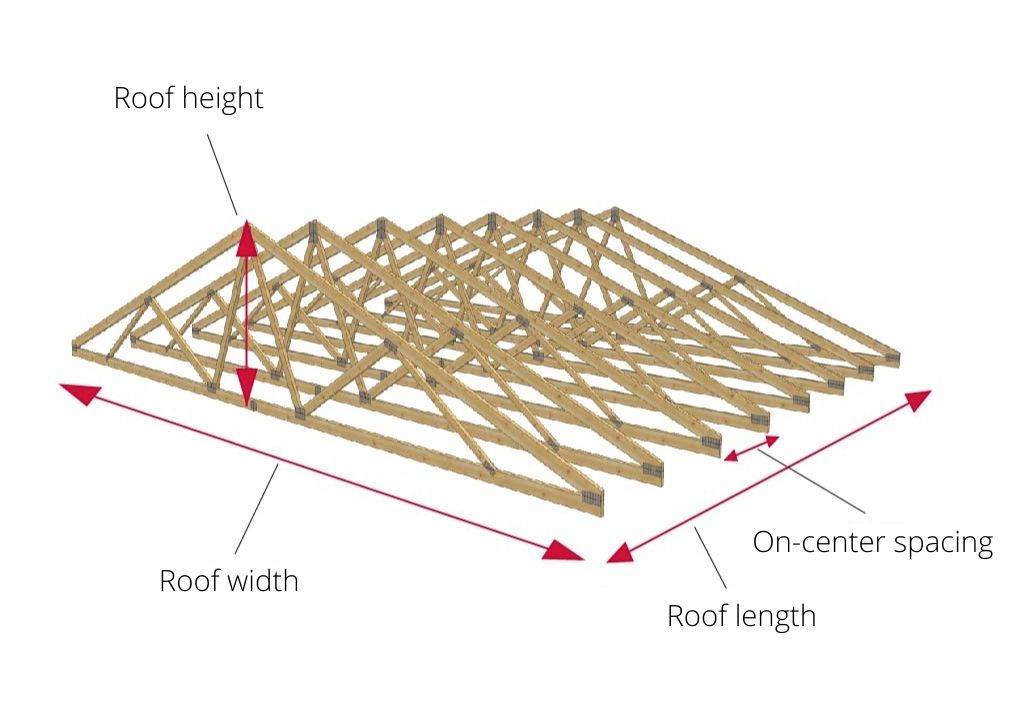

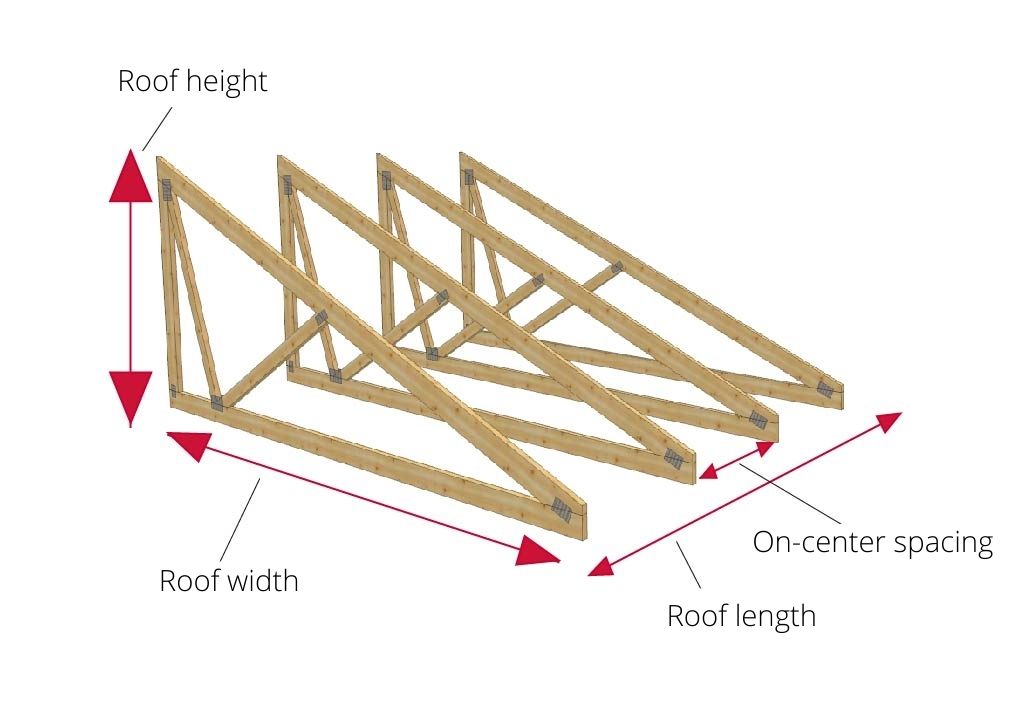

To find out the approximate price of roof trusses, select the roof type and fill in the required fields.

ROOF TRUSSES CALCULATOR

Please note: This calculation is an estimate and does not account for factors such as the selected roofing material, potential overhangs, snow and wind loads, or other structural considerations. As a result, the final quoted price may vary significantly.

This estimate is based on the most commonly used spacing between trusses – 600mm on centre.

Keep in mind that increasing the spacing reduces the quantity of timber required, which in turn lowers the overall cost.

The calculation is approximate, as it does not take into account the planned type of roofing, possible overhangs, snow loads, etc. Therefore, the actual offer price can vary significantly.

In this calculation, the most popular on-center spacing between trusses is 600mm.

Note that the larger the on-center spacing, the smaller the amount of timber required.

Consequently, the price is lower.